|

We have shielding gas for the welder now. It welds much more cleanly. Here are some knob positions that seem to work well. Be sure to open the gas valve on the top of the cylinder before use, and close it after. Leave the pressure-setting knob where it is. Run the exhaust fan when using gas.  I hooked up the leads wrong at first. See the welds in the middle below. The nicer welds on the sides are after we changed the leads.

0 Comments

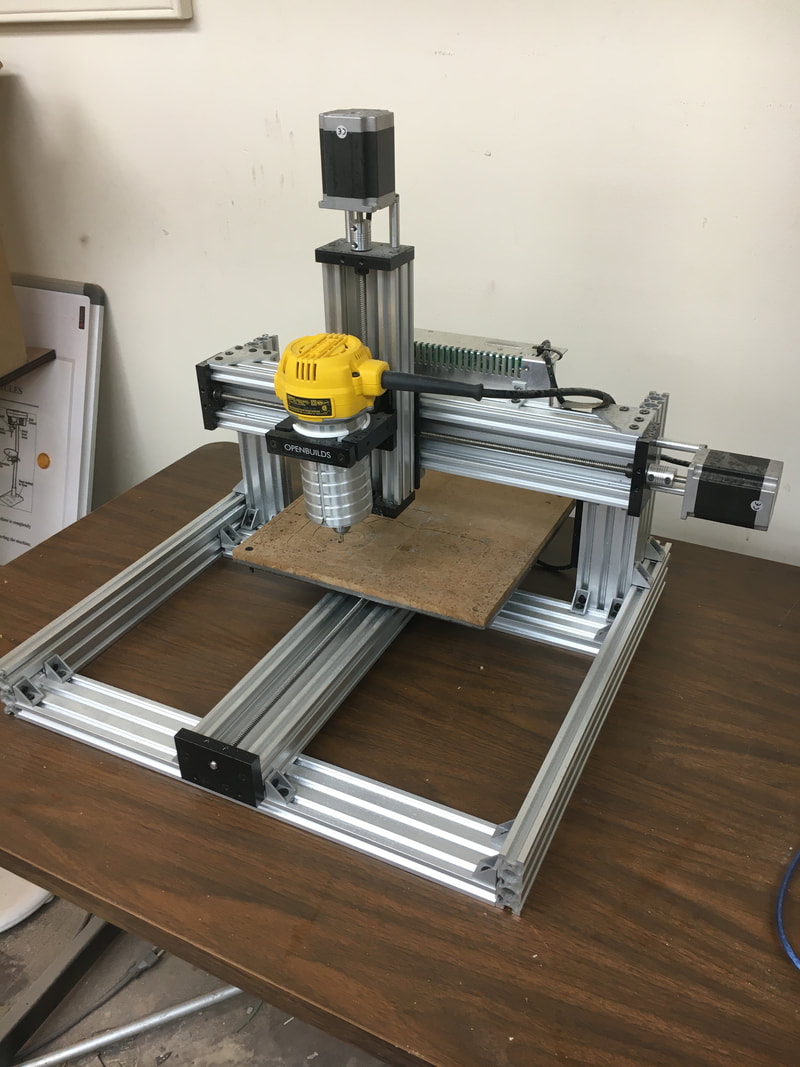

We have a new CNC machine. We will have a class on it soon. It can cut wood and Aluminum up to about 3/8-inch. Please get instruction before using - it has few safety features and CNC machines love to crash

Forgot to add:

The meeting is 6 pm Wednesday Sept 2, 2020 Our tireless makers have created a virtual meeting setup just for you!

You can join in by using this Discord link https://discord.gg/zvRpfVU We hope to see some of you who have been avoiding the space due to the virus. Topics: Metal casting Soap box derby car: will they have the race in September Fencing the outdoor area We are making great progress on our metal casting furnace. We plan to cast aluminum and maybe brass. The furnace is built from an old propane tank lined with refractory. A weed torch will heat it. Wires are welded into the lid to support the refractory. Cardboard tubes and soup cans create vent holes. We used an old paint can as the form to make space for the crucible.

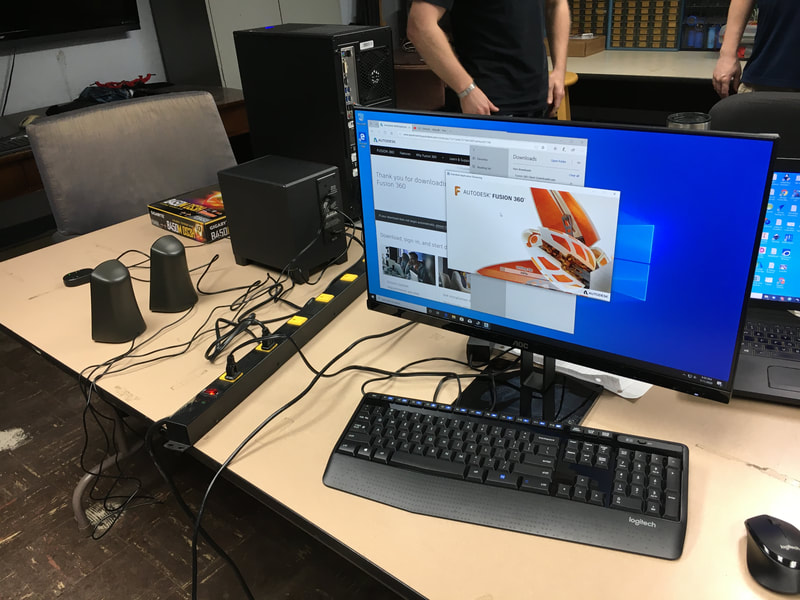

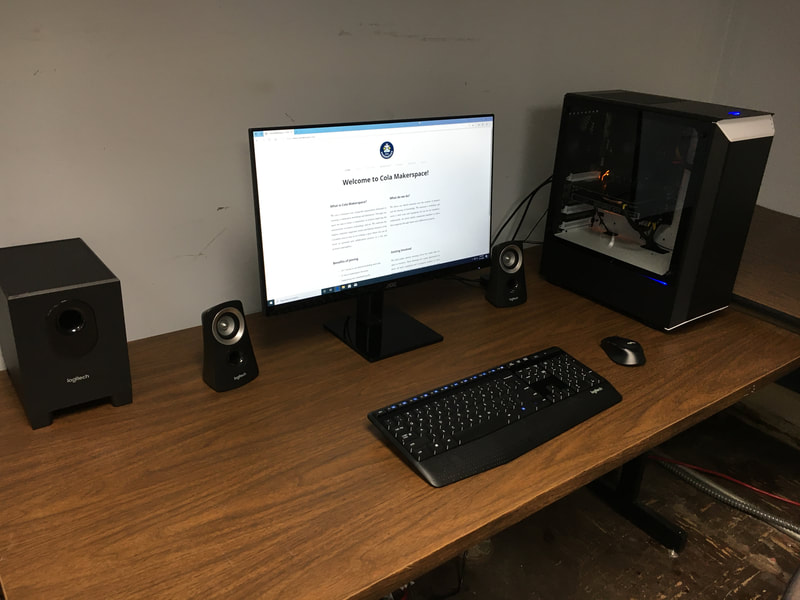

Our original furnace was charcoal fired and it was a nuisance. We also made our own refractory, greensand, and crucible. This time, we bought those items. Much easier! We had our PC build class today and assembled the new PC for makerspace use. You can see the progress below. The PC is in the main room. We installed Autocad Fusion 360. What else would you like installed? Thanks to our instructor!

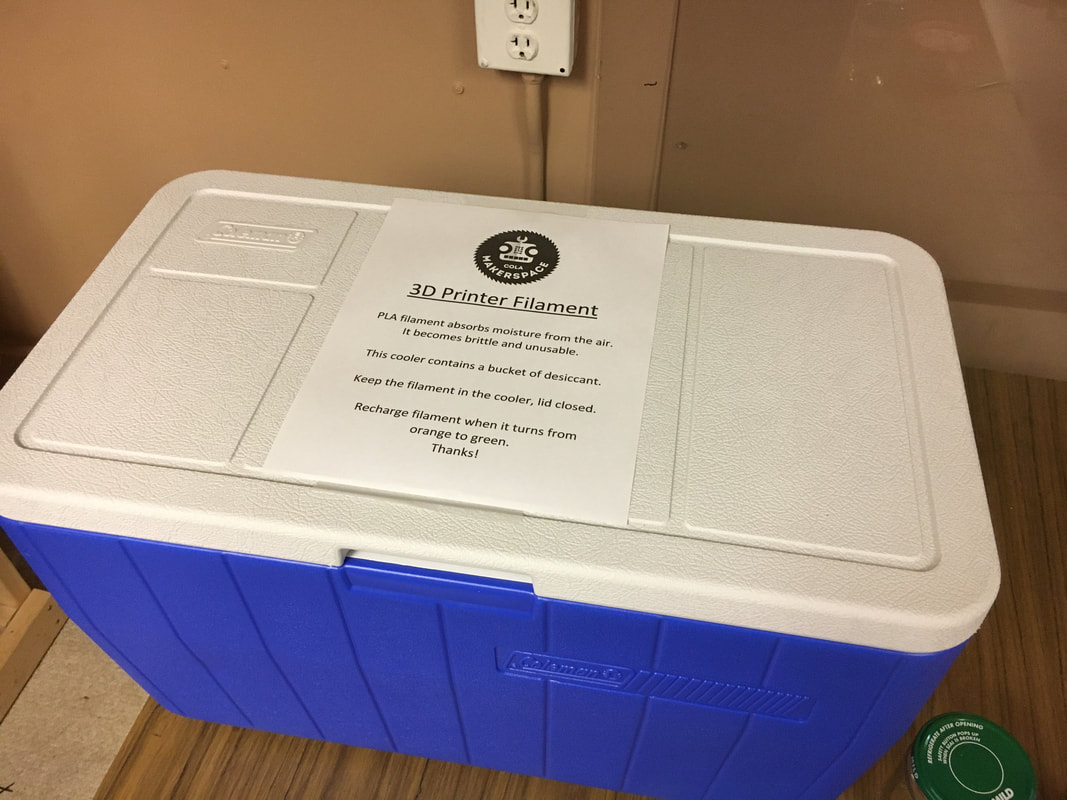

PLA filament absorbs moisture from the air and becomes brittle, or so I'm told. I know the black filament has been left out for several years and breaks under its own weight.

We now have a cooler with Desiccant! The desiccant is the orange stuff in the tub on the left. The instructions to recharge it are on the blue bag behind the tub. It is supposed to turn green when it is saturated. You can recharge it in the makerspace microwave or take it home and put it in the oven. Please keep the filament in the cooler with the lid closed. Might as well keep the ABS in there as well. The paper printer in the office is up and running. You can plug in the USB or use it through wireless.

The race isn't until April 2021, but we did some more work. The rear axle bearing are here. Next is to cut holes to bolt them on and to thread the 3/4 inch axle ends.

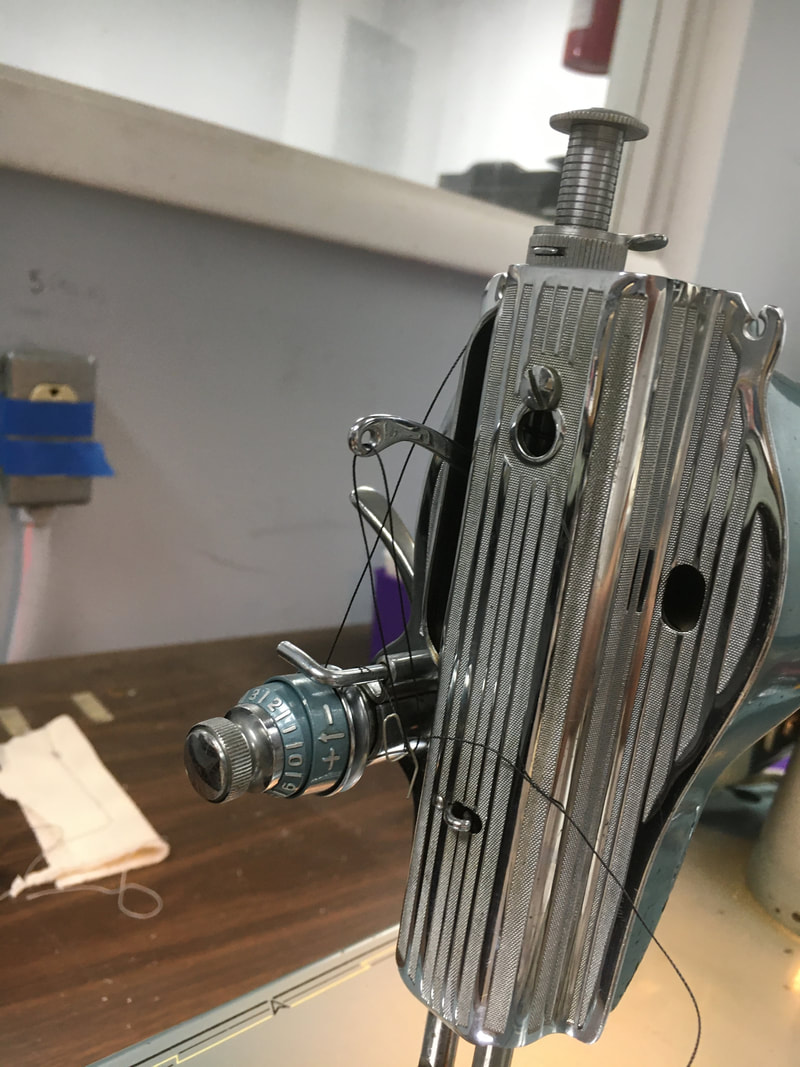

We also removed the old counter and opened the roll-up door to give us more space I needed a boat cover for my 14 ft Sunfish, so I decided to make one. The old, blue sewing machine in the craft corner did a great job. It only does straight stitches, but went through the double layers of Sunbrella with no problems. My newer sewing machine at home didn't work so well! Threading the machine is a little different, so here are some photos.  Loading the bobbin I probably stitched at least 30 linear feet, no problems!

|

Location |

|

RSS Feed

RSS Feed